The Shield of the Fleet: UIC Leaflet 842-2 Paint Specifications

Protect rolling stock assets effectively. A guide to UIC Leaflet 842-2, detailing technical specifications for paint supply, durability tests, and corrosion protection.

Introduction to UIC Leaflet 842-2

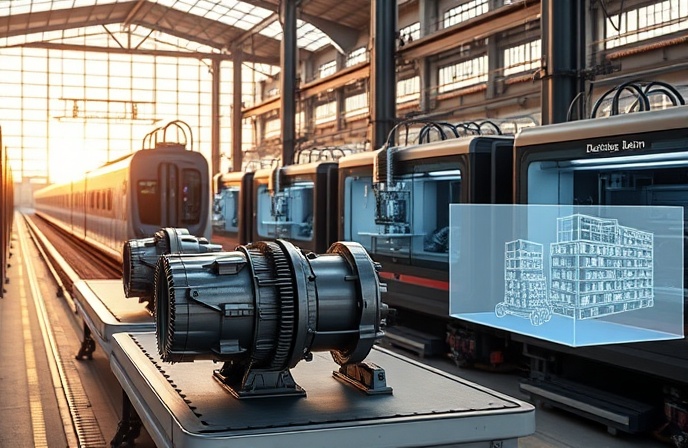

The longevity of railway vehicles depends heavily on their “skin.” UIC Leaflet 842-2, titled “Technical specification for the supply of paint products for the protection of railway vehicles and containers,” is the definitive standard for ensuring that the coatings used on rolling stock can survive the harsh railway environment.

Unlike stationary steel structures, trains are subjected to abrasive brake dust, high-pressure washing with strong chemicals, UV radiation, and physical impacts at high speeds. UIC 842-2 provides the framework for selecting and testing paint systems that meet these unique challenges.

Snippet Definition: What is UIC 842-2?

UIC Leaflet 842-2 is a technical standard issued by the International Union of Railways that defines the quality requirements, approval procedures, and testing methods for paint products used on railway vehicles (locomotives, coaches, wagons) and containers. It ensures the coating system provides adequate corrosion protection and aesthetic durability.

Scope and Application

The leaflet covers the entire lifecycle of the coating process, from the supply of the liquid paint to the final acceptance of the painted surface. It is applicable to:

- Exterior Surfaces: Car bodies exposed to weather and mechanical stress.

- Interior Surfaces: Areas requiring resistance to wear and passenger contact.

- Underframes: High-corrosion zones exposed to ballast hits and moisture.

Key Technical Requirements

To obtain approval under UIC 842-2, a paint system must pass a series of rigorous laboratory tests. These are more specialized than general industrial standards.

1. Physical Resistance

- Adhesion: Verified using the cross-cut test (grid method) to ensure the paint does not peel off the substrate.

- Impact Resistance: The coating must not crack or delaminate when struck by flying debris (ballast stones).

- Elasticity: The paint must flex with the vehicle body vibrations without cracking.

2. Chemical and Environmental Resistance

- Washing Agents: Trains are washed frequently with acidic or alkaline solutions. The paint gloss must not degrade rapidly under these conditions.

- Graffiti Removal: Modern railway paints often require “anti-graffiti” properties, allowing aggressive solvents to remove vandalism without damaging the original topcoat.

Comparison: UIC 842-2 vs. ISO 12944

While ISO 12944 is the global standard for corrosion protection of steel, UIC 842-2 is tailored specifically for the dynamic and aesthetic needs of railways.

| Feature | UIC Leaflet 842-2 | ISO 12944 |

|---|---|---|

| Primary Focus | Railway Rolling Stock & Containers. | General Steel Structures (Bridges, Buildings). |

| Aesthetic Requirements | High (Gloss retention and color stability are critical). | Moderate (Focus is primarily on rust prevention). |

| Chemical Resistance | Specific tests for railway washing agents and graffiti removers. | General atmospheric and industrial pollution resistance. |

| Test Duration | Accelerated weathering tests specific to train operations. | Based on corrosivity categories (C1 to C5). |

Testing and Certification

Manufacturers wishing to supply paint to railway operators must submit samples for type testing. The “approval” is usually valid for a specific period or until the formulation changes. This process minimizes the risk of paint failure, which could lead to expensive repainting and downtime for the fleet.