Europe’s EN 13230-3: The Standard for Twin-Block Track Safety

Understanding EN 13230-3: Twin-Block Reinforced Concrete Sleepers

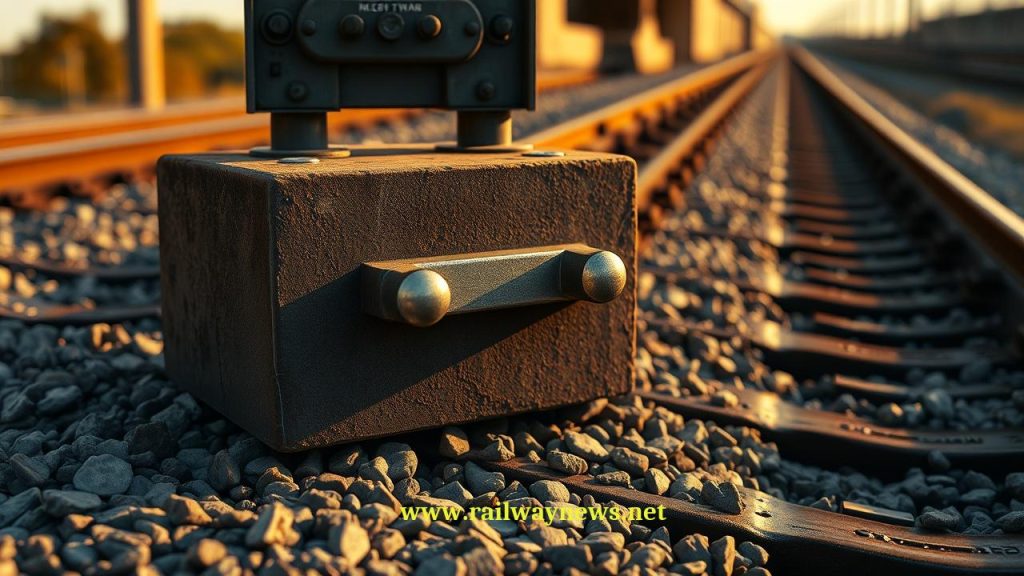

EN 13230-3 is a key European Standard within the railway sector that specifies the requirements for the design, manufacture, and testing of twin-block reinforced concrete sleepers. As part of the broader EN 13230 series, this particular document focuses exclusively on sleepers constructed from two concrete blocks linked by a steel tie bar, a design distinct from their monoblock counterparts.

The standard’s primary objective is to ensure that these critical track components provide the necessary safety, durability, and performance under the demanding operational conditions of a railway network. It establishes a common technical basis for manufacturers, railway infrastructure managers, and regulatory bodies across Europe, promoting interoperability and a consistent level of quality.

Core Technical Specifications and Requirements

EN 13230-3 outlines a comprehensive set of technical criteria covering materials, geometry, and mechanical performance. Compliance with these criteria is mandatory for a product to be certified against the standard.

Materials and Components

The standard is precise about the quality of materials used to ensure the sleeper’s long-term integrity.

- Concrete: The concrete used for the blocks must meet specific strength and durability classes defined in other European standards (like EN 206). This includes requirements for minimum compressive strength, water absorption, and resistance to freeze-thaw cycles and chemical attack.

- Reinforcement: The steel reinforcement within the concrete blocks must conform to relevant standards for reinforcing steel. The standard specifies the type, grade, and placement of the reinforcement to manage tensile stresses effectively.

- Connecting Tie Bar: The steel tie bar is a critical component responsible for maintaining the correct track gauge. It must be made from steel with specified mechanical properties and, crucially, must be protected against corrosion, often through galvanization or other suitable coatings, to prevent premature failure. The connection between the tie bar and the concrete blocks is also a point of focus, ensuring a robust bond.

Geometrical Tolerances

Precise geometry is fundamental for correct track installation and performance. EN 13230-3 defines strict dimensional tolerances for:

- Overall Dimensions: The length, width, and height of the concrete blocks.

- Track Gauge: The distance between the rail seats, which is the most critical geometric parameter.

- Rail Seat Inclination: The specified cant (typically 1:20 or 1:40) that the rail sits on.

- Positioning of Fastenings: The location and alignment of inserts or holes for the rail fastening system.

- Flatness and Straightness: Tolerances for the sleeper surfaces to ensure stable support.

Mechanical Performance and Testing Procedures

To verify that the sleepers can withstand the loads imposed by rail traffic, EN 13230-3 mandates a series of rigorous type tests. These tests simulate the forces experienced by the sleeper in the track.

- Static Bending Tests: These tests determine the structural capacity of the sleeper.

- Positive Bending Test at Rail Seat: A downward load is applied at the rail seat to simulate the force from a wheel. The sleeper must withstand a specified test load without cracking and a higher load without failure.

- Negative Bending Test at Center: An upward load is applied to the center of the tie bar (or a downward load on the ends) to simulate the tamping forces and the dynamic uplift that can occur between axles.

- Fatigue Test: This dynamic test assesses the sleeper’s long-term durability by applying a repeated, cyclical load at the rail seat to simulate the passage of millions of train axles. The sleeper must endure the test without significant degradation or cracking.

- Tie Bar Bond Test: A specific test is performed to measure the pull-out strength of the connecting tie bar from the concrete blocks, ensuring the integrity of the connection throughout the sleeper’s service life.

Comparison: Twin-Block (EN 13230-3) vs. Monoblock (EN 13230-2) Sleepers

Choosing between a twin-block and a monoblock sleeper depends on the specific application, track conditions, and economic considerations. The following table highlights their key differences.

| Feature | Twin-Block Sleeper (EN 13230-3) | Monoblock Sleeper (EN 13230-2) |

|---|---|---|

| Structure | Two reinforced concrete blocks connected by a flexible or rigid steel tie bar. | A single, continuous prestressed concrete beam. |

| Weight & Handling | Generally lighter and can be handled as two separate pieces before the tie bar is fixed, easing manual installation. | Significantly heavier, requiring mechanical equipment for handling and installation. |

| Track Elasticity | The steel tie bar provides a degree of lateral flexibility, which can be advantageous in certain track forms and curves. | Very rigid and stiff, providing high stability, which is ideal for high-speed lines. |

| Ballast Interaction | Offers good longitudinal and lateral ballast resistance due to the two distinct blocks. | Provides excellent and uniform support, with high resistance to track buckling. |

| Common Applications | Secondary lines, sidings, industrial tracks, sections with sharp curves, and in networks where manual track work is common. | Main lines, high-speed rail, heavy haul lines, and tracks with high traffic density. |

| Failure Mode | Failure often localized to one block or the tie bar. The tie bar is a potential point of weakness if corrosion protection fails. | A crack can potentially propagate across the entire sleeper, though prestressing provides high resilience. |

Conclusion: The Role of EN 13230-3 in Railway Infrastructure

EN 13230-3 serves as a vital benchmark for ensuring the quality and reliability of twin-block reinforced concrete sleepers. By standardizing design inputs, material quality, and verification methods, it gives railway authorities confidence that the components they procure will perform safely and effectively over their intended design life. While monoblock sleepers are more common on high-speed and heavy-haul lines, the twin-block design remains a relevant and cost-effective solution for a wide range of other railway applications, and this standard is central to its continued success and safe implementation.