Rail Vision’s CAS: Revolutionizing Rio Tinto’s Safety

Introduction

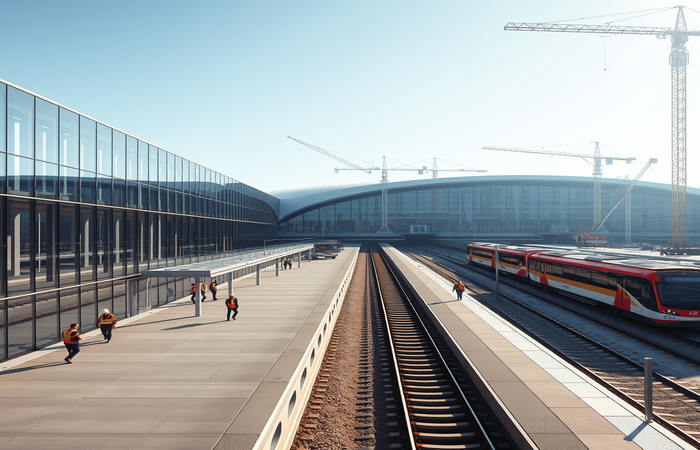

This article explores the strategic partnership between Foresight Autonomous’ affiliate, Rail Vision, and Hitachi Rail STS Australia to enhance the safety and efficiency of Rio Tinto’s extensive railway network in Australia. The collaboration focuses on deploying Rail Vision’s Collision Avoidance System (CAS) on Rio Tinto’s fleet of nearly 220 locomotives. This project represents a significant step forward in leveraging advanced technologies to improve railway safety, operational efficiency, and overall network performance. The implementation involves a phased approach, starting with a proof-of-concept project to assess the system’s viability and effectiveness before potential full-scale deployment. This case study highlights the growing importance of Intelligent Transportation Systems (ITS) in the rail industry and the potential for innovative technologies to address critical safety and operational challenges. The success of this project could serve as a model for future deployments of similar systems globally, demonstrating the effectiveness of advanced collision avoidance technology in enhancing railway safety and efficiency.

Proof-of-Concept and System Integration

The initial phase of the project involves a comprehensive proof-of-concept, managed by Hitachi Rail STS Australia as the project integrator. This phase aims to rigorously test Rail Vision’s CAS in the challenging operational environment of Rio Tinto’s railway network. This entails live demonstrations and data acquisition to evaluate the system’s performance under real-world conditions, including various weather conditions and operational scenarios. The system’s ability to detect potential threats, such as trespassers, obstacles on the tracks, or equipment malfunctions, will be thoroughly assessed. The data collected will be crucial in validating the system’s accuracy, reliability, and overall suitability for integration into Rio Tinto’s existing infrastructure. This methodical approach ensures a robust evaluation before any significant investment in a full-scale deployment.

System Deployment and Customization

Following a successful proof-of-concept, the project proceeds to system deployment and customization. This phase will focus on integrating Rail Vision’s CAS into Rio Tinto’s locomotives. This integration requires careful planning and execution to ensure seamless operation with the existing onboard systems. Furthermore, Rail Vision will provide necessary support, customization, and development services to tailor the system to meet Rio Tinto’s specific operational requirements. This customization may include adjusting parameters to optimize the system’s performance in the unique geographical and operational context of the Rio Tinto network. The ability to customize the system showcases its flexibility and adaptability, making it a potentially valuable solution for a wide range of railway operations.

Long-Term Operational Benefits and Scalability

Successful implementation of Rail Vision’s CAS offers several significant long-term benefits for Rio Tinto. The enhanced collision avoidance capabilities improve safety by reducing the risk of accidents caused by human error or unforeseen circumstances. This translates to increased operational efficiency by minimizing costly downtime associated with accidents and repairs. Furthermore, the system’s data collection and analysis capabilities can provide valuable insights into operational patterns, which can further optimize network management and resource allocation. The scalability of the system is a key advantage, allowing for potential future expansion to other parts of Rio Tinto’s network or even adoption by other railway operators. This long-term perspective highlights the significant return on investment potential of this advanced safety technology.

Conclusions

The collaboration between Rail Vision, Hitachi Rail STS Australia, and Rio Tinto marks a significant advancement in railway safety technology. The phased approach, beginning with a thorough proof-of-concept, demonstrates a commitment to rigorous testing and validation before full-scale deployment. The project’s success hinges on the seamless integration of Rail Vision’s Collision Avoidance System (CAS) into Rio Tinto’s existing infrastructure and operational workflows. Successful implementation promises a substantial improvement in safety, operational efficiency, and overall network performance. The system’s scalability offers the potential for wider adoption within Rio Tinto’s operations and broader applicability to other railway networks globally. The project highlights the growing importance of Intelligent Transportation Systems (ITS) in enhancing railway safety and efficiency, paving the way for future advancements in this critical sector. The potential for improved safety, reduced operational costs, and data-driven optimization makes this initiative a compelling example of how technological innovation can transform the railway industry. The comprehensive testing and customization phases ensure that the system is not only effective but also tailored to the unique needs of Rio Tinto’s network, maximizing its potential benefits. The long-term impact of this project extends beyond Rio Tinto, potentially setting a new standard for railway safety and efficiency worldwide.