MxV Rail Expands Rail Component Testing Lab Capabilities

MxV Rail Expands Laboratory Capabilities for Rail Component Testing

Pueblo, Colorado – October 26, 2023 – The rail industry is constantly evolving, with advancements in technology and a relentless focus on safety and efficiency. To support these advancements, robust testing and analysis of rail components are crucial. MxV Rail (formerly Transportation Technology Center, Inc. or TTCI), a leading provider of rail testing and technology solutions, has recently expanded its laboratory capabilities. This expansion includes new testing equipment and enhanced environmental control, solidifying MxV Rail’s commitment to providing cutting-edge research and development services. This article will delve into the specific additions to their laboratory, the importance of these enhancements, and their impact on the future of the rail industry.

Strengthening Testing Capabilities

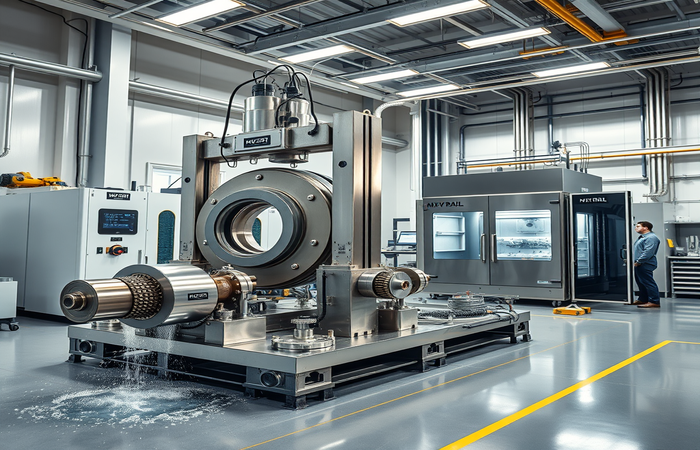

The recent expansion at MxV Rail represents a significant investment in the future of rail component testing. The addition of a bearing rig tester equipped with a servo-hydraulic computer-controlled load frame, along with a water spray feature, allows for comprehensive analysis of bearing performance under various simulated operating conditions. This is particularly important, as bearings are critical components in rolling stock, and their failure can lead to costly delays and safety concerns. Furthermore, the introduction of a custom-designed tie wear tester enables MxV Rail to evaluate the durability and performance of railway ties, a key element in maintaining track infrastructure. The completion of its first commercial test demonstrates the immediate applicability of this new technology. These advancements provide a more detailed and realistic testing environment, which is critical for the rail industry.

Environmental Control for Comprehensive Analysis

Another key addition to MxV Rail’s laboratory is an environmental chamber. This chamber allows for testing of components in a controlled environment, with temperatures ranging from -85 to 185 degrees Fahrenheit (-65 to 85 degrees Celsius). This capability is crucial because rail components must withstand extreme temperature variations depending on the geographical location and the time of year. By simulating these conditions, MxV Rail can assess the performance and reliability of components under a wider range of operating scenarios, contributing to improved safety and longevity. The chamber was donated by a member of the Association of American Railroads (AAR), highlighting the collaborative nature of the industry and its commitment to shared resources for research and development.

Industry Impact and Future Outlook

The expansion of MxV Rail’s laboratory capabilities has a substantial impact on the entire rail industry. The ability to conduct more rigorous and realistic testing of components will lead to several key benefits. First, it will allow manufacturers to develop and refine components that are more durable, reliable, and efficient. Second, it will provide railroads with the data and insights needed to make informed decisions about component selection, maintenance, and replacement, optimizing operational performance and reducing costs. Third, it will contribute to enhanced safety by identifying potential failure points and enabling proactive mitigation strategies. The enhanced testing capabilities provided by MxV Rail are set to play an important role in improving the standards within the rail industry.

Conclusion

MxV Rail’s recent investment in its laboratory capabilities signals a positive step forward for the rail industry. The introduction of new testing equipment, including the bearing rig tester and tie wear tester, along with the environmental chamber, significantly enhances the ability to analyze the performance and durability of rail components. This will lead to safer, more efficient, and more cost-effective railway operations. These expanded capabilities are a testament to MxV Rail’s commitment to providing cutting-edge research and development services and supporting the rail industry’s continuous improvement. The industry as a whole benefits from this investment, as it fosters innovation, improves safety, and drives operational efficiency. As the industry continues to evolve, with advancements in areas such as automation, electrification, and high-speed rail, rigorous testing and analysis will be even more critical. MxV Rail’s enhanced laboratory is well-positioned to provide the insights and data needed to lead the industry into the future, helping to ensure a safe, reliable, and sustainable railway network for years to come.

Brief Company Summary:

MxV Rail: MxV Rail, formerly known as Transportation Technology Center, Inc. (TTCI), is a subsidiary of the Association of American Railroads (AAR). Located in Pueblo, Colorado, MxV Rail is a leading provider of rail testing, research, and technology solutions. The company offers a wide range of services, including component testing, track and infrastructure testing, and training. MxV Rail’s mission is to advance the safety, efficiency, and sustainability of the rail industry through innovation and collaboration.