UIC 541-3: Disc Brake Pads Certification & Friction Coefficient Standards

UIC 541-3 (Chapter 5) establishes the tribological certification standards for Rolling Stock disc brake pads. This guide details the mandatory Dynamometer Tests for verifying friction coefficient ($\mu$) stability, the thermal capacity requirements for preventing “Brake Fade” during Alpine descents, and the geometric interchangeability standards for Organic and Sintered pads.

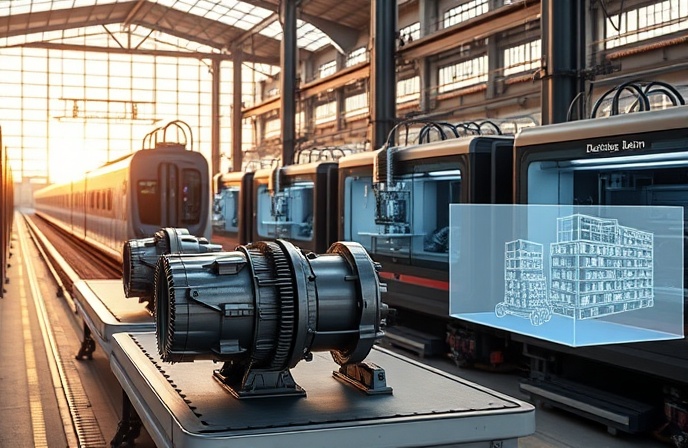

UIC 541-3 Chapter 5 sets the global benchmark for the certification of Disc Brake Pads used in rolling stock. Unlike cast-iron blocks acting on the wheel tread, disc brake pads must dissipate massive kinetic energy through dedicated axle-mounted or wheel-mounted discs.

This standard defines the mandatory Dynamometer Tests required to validate the friction material’s performance. It ensures that the friction coefficient ($\mu$) remains stable regardless of speed (up to 300+ km/h), clamping force, or extreme weather conditions (wet/dry).

1. The Friction Coefficient ($\mu$): Preventing “Fading”

The core of UIC 541-3 is the stability of friction. A safe brake pad must provide a consistent stopping force. The standard tests for:

- Mean Friction Coefficient: typically required to be around 0.35 – 0.45 for organic pads.

- Fading Resistance: The pad must not lose friction power when the disc temperature exceeds 400°C during emergency braking.

- Wet Performance: The material must recover its friction level quickly after passing through water sprays (simulating rain/snow).

2. Classification of Brake Pads

Brake pads are categorized based on their material composition and intended operational duty (Suburban vs. High Speed). UIC 541-3 defines the limits for these classes:Pad Material Typical Application Critical Characteristics Organic / Composite Passenger Coaches (RIC) Quiet operation, moderate thermal limit. Standard friction $\mu \approx 0.35$. Sintered Metal High-Speed Trains / Locos High thermal conductivity, stable at extreme temps (>600°C), but noisier. Drag Braking Test Mountain Operations Simulates a 40km descent (e.g., The Alps) maintaining constant braking power without burning.

3. Interchangeability (Fitment)

Just like brake blocks in UIC 542, brake pads must fit into standard holders (calipers) to allow cross-border maintenance. UIC 541-3 standardizes:

- Dovetail Guides: The geometric shape of the backing plate ensuring the pad slides correctly into the caliper holder.

- Pad Thickness: Typically 35mm (inclusive of backing plate), defining the wear limit sensors’ calibration.

- Marking: Every pad must carry the UIC code, batch number, and manufacturer ID for traceability in case of accidents.

4. The Homologation Gauntlet

A brake pad cannot be installed on a train based on a datasheet alone. It must undergo a rigorous Bench Test (Dynamometer) where a flywheel simulates the train’s inertia. Only after passing the bench test can it proceed to In-Service Field Testing (typically 1 year of revenue service) to prove its durability and disc-