EN 15827: Europe’s Standard For Safe & High-Performance Bogies

Unlock EN 15827: the essential European standard for railway bogies. It ensures structural integrity, dynamic performance, and safety, guaranteeing interoperability and passenger comfort.

An In-Depth Technical Guide to EN 15827: Requirements for Bogies and Running Gears

EN 15827 is a crucial European standard that specifies the technical requirements for the design, manufacturing, and validation of bogies and running gears for railway vehicles. It serves as a foundational document for ensuring the safety, performance, and interoperability of rolling stock across European networks by establishing a common framework for these critical assemblies.

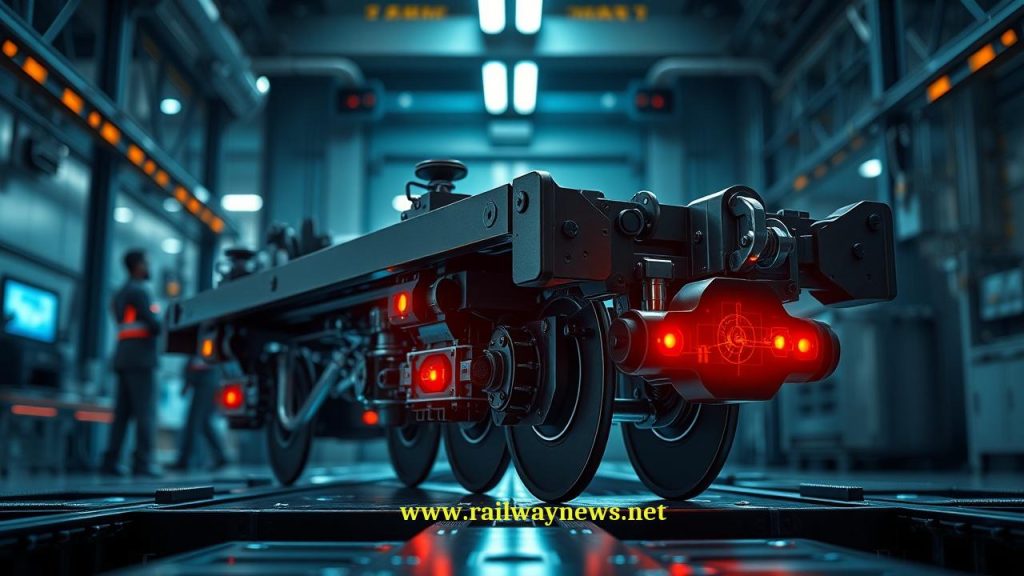

The bogie, or running gear, is one of the most vital components of a railway vehicle. It is responsible for supporting the carbody, guiding the vehicle along the track, ensuring ride comfort, and transmitting traction and braking forces. Given its direct interface with the track and its role in vehicle dynamics, the integrity and performance of the bogie are paramount to safe and efficient railway operations.

Core Objectives and Scope of the Standard

Primary Goals of EN 15827

The standard is designed to achieve several key objectives, forming a comprehensive basis for bogie development and approval:

- Ensure Structural Integrity: To define the loads, stress limits, and fatigue life requirements that a bogie frame and its components must withstand throughout their operational life.

- Define Performance Criteria: To establish clear and measurable criteria for dynamic behaviour, including running safety (derailment and instability), ride quality, and track interaction.

- Provide a Validation Framework: To specify a structured process of analysis, static testing, and dynamic on-track testing to demonstrate compliance with the requirements.

- Promote Interoperability: By creating a harmonised set of requirements, the standard facilitates the approval and operation of rolling stock across different national railway networks within Europe.

Scope and Applicability

EN 15827 applies to bogies and running gears for all types of mainline railway vehicles, including locomotives, passenger coaches, freight wagons, and multiple units (EMUs/DMUs). While it provides a comprehensive framework, it is intended to be used in conjunction with other specific standards that cover individual components such as wheelsets (EN 13749) or axleboxes.

Key Technical Requirements of EN 15827

The standard details a wide range of technical specifications that must be met. These can be grouped into several core areas.

Structural Integrity and Design Loads

A fundamental part of EN 15827 is the definition of load cases that the bogie structure must be designed to resist. The standard requires that the design process includes a thorough analysis, typically using Finite Element Method (FEM), to verify that stresses within the structure remain within acceptable limits under all operational scenarios. Key load cases include:

- Exceptional Loads: High-magnitude, infrequent loads such as maximum vertical payload, lifting/jacking scenarios, and buffing impacts. The structure must withstand these without permanent deformation.

- Normal Service (Fatigue) Loads: The repetitive loads experienced during normal operation, such as vertical bouncing, transverse forces during curving, and traction/braking forces. The design must demonstrate adequate fatigue life to prevent crack initiation and propagation.

The fatigue assessment is critical and is typically carried out using methods like the Goodman diagram or specific regulations detailed in other standards referenced by EN 15827.

Dynamic Behaviour and Vehicle-Track Interaction

This section addresses the performance of the bogie in motion. The standard sets limits on key dynamic parameters to ensure safety and comfort. The primary requirements are:

- Running Safety: The bogie must be inherently stable and prevent derailment. This involves assessments against derailment criteria (e.g., Y/Q ratio) and protection against “hunting,” an unstable self-sustaining lateral oscillation that can occur at high speeds.

- Ride Quality: The suspension system (primary and secondary) must effectively isolate the carbody from track irregularities. Ride comfort is quantified by measuring accelerations within the vehicle, which must remain below specified limits (often defined in standards like EN 12299).

- Track Loading: The bogie should be designed to minimise forces exerted on the track to reduce wear and tear on both the wheels and the rails. This includes limiting quasi-static and dynamic wheel forces.

Materials and Manufacturing

EN 15827 mandates strict controls over the materials and manufacturing processes used for bogie frames and safety-critical components. It requires that materials, particularly steels for welded structures, possess adequate strength, toughness, and fatigue resistance for the railway environment. Manufacturing processes, especially welding, must be performed according to certified procedures, with EN 15085 (Welding of Railway Vehicles and Components) being the key reference standard for ensuring the quality and integrity of welded joints.

Validation and Testing Procedures

To prove compliance, EN 15827 requires a rigorous, multi-stage validation program that combines theoretical analysis with physical tests.

Static Tests

Before any on-track testing, the bogie frame must undergo a series of static tests in a laboratory. A completed bogie frame is placed in a test rig and subjected to calibrated loads that simulate the exceptional and fatigue load cases defined in the design phase. Strain gauges are used to measure the resulting stresses, which are then compared against the calculated values from the FEM analysis to validate the design model.

Dynamic and On-Track Tests

Once the static strength is confirmed, the bogie is subjected to on-track tests to validate its dynamic performance. A fully instrumented vehicle is run on a representative section of track under various speed and track quality conditions. Measurements are taken to verify compliance with the requirements for running safety, ride quality, and track loading.

Comparison of Validation Tests

| Feature | Static Tests | Dynamic (On-Track) Tests |

|---|---|---|

| Purpose | To verify the structural strength and fatigue resistance of the bogie frame. | To validate the performance of the bogie in terms of safety, comfort, and track interaction. |

| Methodology | Application of controlled, calibrated loads on a stationary bogie frame in a test rig. | Operating an instrumented vehicle on a real track at various speeds and conditions. |

| Key Parameters Measured | Stress and strain at critical locations, and structural deformation. | Wheel-rail forces (Y/Q ratio), vehicle body accelerations, bogie stability. |

| Typical Outcome | Validation of the structural design calculations (FEM) and confirmation of fatigue life. | Confirmation that the bogie meets all performance criteria for safe and comfortable operation. |

Relationship with Other Railway Standards

EN 15827 does not exist in isolation. It is part of the comprehensive ecosystem of European railway standards and frequently references other norms for specific details. Key related standards include:

- EN 12663 (Railway applications – Structural requirements of railway vehicle bodies): Defines the loads and requirements for the carbody, which interfaces directly with the bogie.

- EN 13749 (Railway applications – Wheelsets and bogies – Method of specifying the structural requirements of bogie frames): Provides more detailed methodologies specifically for the structural design and validation of bogie frames.

- EN 15085 (Welding of railway vehicles and components): The mandatory standard for controlling the quality of all welding activities during bogie manufacturing.

- EN 12299 (Railway applications – Ride comfort for passengers): Defines the methodology for measuring and evaluating passenger ride comfort.

Conclusion

EN 15827 is an indispensable standard in the modern railway industry. By providing a detailed and robust set of requirements for the design, manufacture, and validation of bogies, it underpins the safety and performance of rolling stock. Its framework ensures that bogies are not only structurally sound and capable of withstanding the harsh operational environment but also optimised for dynamic performance, leading to safer travel, enhanced passenger comfort, and reduced wear on railway infrastructure. Adherence to EN 15827 is a non-negotiable step in the process of bringing new or modified rolling stock into service on the European network.