EU Rail Revolution: DAC’s Impact on Freight

Introduction

The European Union is undertaking a significant modernization effort within its freight rail network, focusing on the transition to Digital Automatic Coupling (DAC). This technological shift promises to revolutionize freight rail operations, addressing longstanding inefficiencies associated with manual coupling. This article delves into the implications of DAC adoption, examining its technological advancements, the benefits for various stakeholders, the challenges associated with widespread implementation, and the broader impact on European freight logistics and environmental sustainability. We will explore the recent successful completion of DAC testing by a Deutsche Bahn (DB)-led consortium and the subsequent presentation to the European Commission, highlighting the significant progress towards broader implementation across the EU’s extensive rail network. This technological upgrade is crucial for enhancing the efficiency, speed, and safety of freight train operations, thereby boosting the overall competitiveness of rail freight and supporting the EU’s green transport initiatives. The transition to DAC involves substantial logistical and financial investment, requiring coordinated efforts from various stakeholders including railway operators, manufacturers, and policymakers. Understanding these complexities and their potential solutions is paramount to successfully achieving the EU’s ambitious goals for rail freight modernization.

The Digital Automatic Coupling (DAC) System

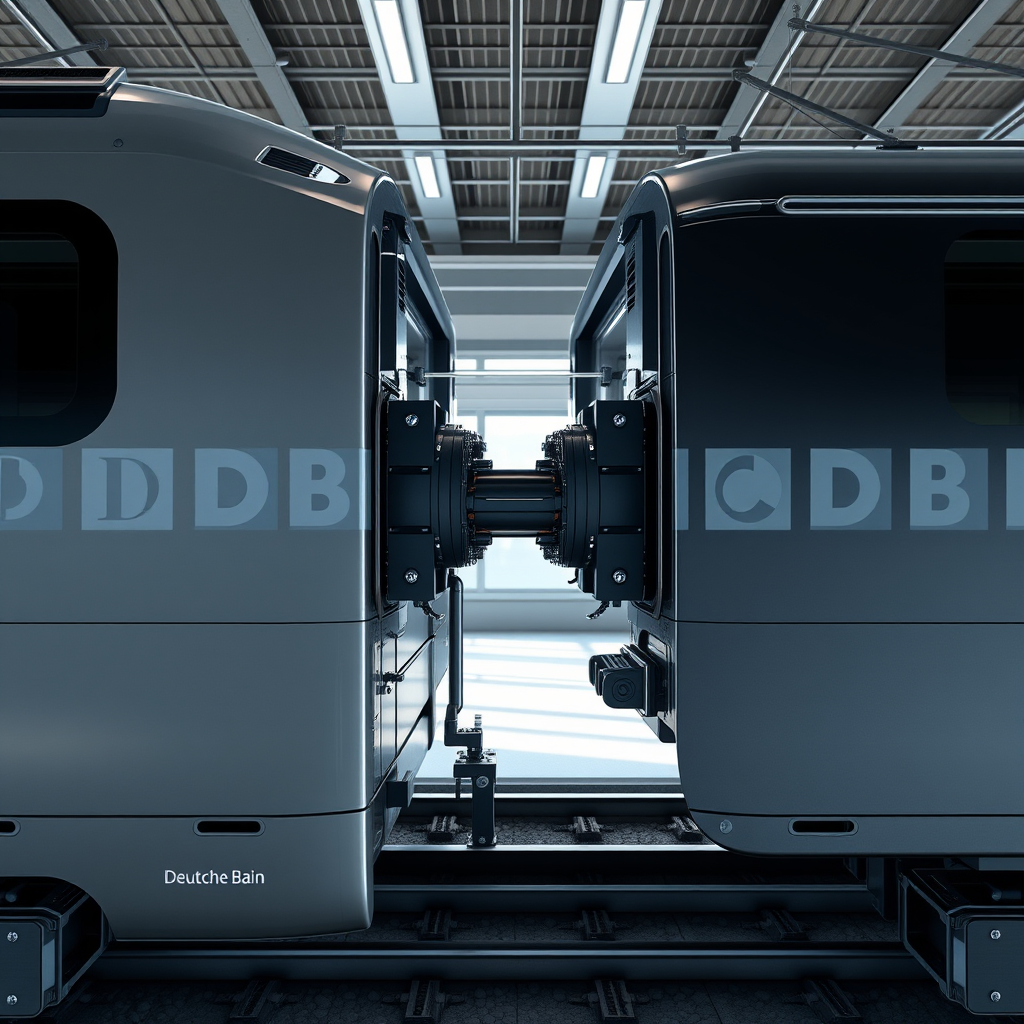

The core of the modernization effort lies in the Digital Automatic Coupling (DAC) system. Unlike traditional manual coupling, which is a time-consuming and labor-intensive process prone to human error, DAC uses automated systems for connecting and disconnecting freight wagons. This automation offers several key advantages. First, it significantly reduces coupling time, leading to increased operational efficiency and throughput. Second, the electronic interface facilitates real-time data transmission between wagons and the locomotive, enabling continuous monitoring of brake systems and other crucial parameters. This enhanced monitoring and control directly improve safety by minimizing the risk of accidents caused by coupling failures or brake malfunctions. The system also allows for continuous power and data lines between wagons, enabling more advanced train control systems and potentially higher operating speeds for freight trains – a feature currently unavailable with conventional manual coupling.

Benefits for Stakeholders

The transition to DAC offers substantial benefits across the railway ecosystem. For railway operators like DB Cargo, DAC translates to increased efficiency, reduced operational costs, and improved service reliability. The faster coupling and uncoupling processes result in shorter turnaround times and higher freight capacity utilization. Furthermore, improved safety reduces the risk of accidents and related financial and reputational losses. For shippers, particularly in industries like steel manufacturing, DAC promises more reliable and efficient supply chains, minimizing delivery delays and transportation costs. This is particularly important for industries relying on just-in-time delivery models. Finally, from an environmental perspective, DAC contributes to a greener transportation sector by increasing the efficiency and competitiveness of rail freight, reducing reliance on less environmentally friendly alternatives like road transport.

Challenges and Implementation Strategies

Despite the substantial benefits, widespread DAC adoption presents considerable challenges. The most significant hurdle is the large-scale retrofitting of existing freight wagons across the EU’s vast network. This requires substantial financial investment and meticulous planning to minimize disruption to existing rail operations. Another challenge lies in ensuring interoperability between different DAC systems from various manufacturers. Standardizing interfaces and protocols is crucial to prevent fragmentation and ensure seamless operation across different railway networks. Furthermore, effective implementation necessitates close collaboration among various stakeholders including railway operators, manufacturers, regulatory bodies, and policymakers. A coordinated approach, involving clear timelines, allocated resources, and effective communication, is essential for successful deployment. This involves not only technological upgrades but also requires appropriate training programs for railway personnel.

Conclusion

The successful testing and presentation of the Digital Automatic Coupling (DAC) system mark a pivotal moment in the modernization of European freight rail. This technology holds the potential to significantly enhance the efficiency, safety, and environmental sustainability of rail freight transport, offering substantial benefits for railway operators, shippers, and the environment. However, realizing the full potential of DAC requires addressing significant challenges associated with widespread implementation. The large-scale retrofitting of existing rolling stock demands substantial investment and careful planning. Ensuring interoperability and coordinating efforts among diverse stakeholders are crucial to achieving a seamless and effective transition. The European Union’s commitment to financing the deployment of DAC demonstrates the strategic importance of this technological advancement in strengthening the European rail network and fostering sustainable freight logistics. The success of this initiative hinges on the continued collaboration between the public and private sectors, technological advancements, and robust regulatory frameworks ensuring standardization and interoperability. Failure to address these challenges risks undermining the potential benefits of DAC and hindering the competitiveness of European rail freight against road transport. The long-term vision for a more efficient, safer, and sustainable European rail freight system is achievable through proactive and coordinated approaches to implementation and a commitment to technological innovation.